In the realm of modern HVAC systems, the role of a Direct Digital Controller (DDC) has become increasingly pivotal. As buildings grow in complexity and the demand for energy efficiency rises, DDCs have emerged as essential components that not only facilitate precise temperature regulation but also optimize overall system performance. A Direct Digital Controller is an intelligent device that utilizes digital technology to monitor and manage HVAC operations, allowing for seamless communication between various system elements.

The ability of DDCs to integrate with advanced sensors and user interfaces enables them to provide real-time data analytics, ensuring that energy consumption is minimized while maintaining occupant comfort. This article delves into the functionality of Direct Digital Controllers, exploring their mechanisms and the advantages they offer in controlling heating, ventilation, and air conditioning systems. Understanding how DDCs work can illuminate the pathway to more sustainable building management and innovative cooling solutions, setting the foundation for efficient climate control in today's fast-paced environment.

Direct Digital Controllers (DDCs) play a pivotal role in modern HVAC systems by enhancing energy efficiency, optimizing performance, and improving user comfort. DDCs utilize digital processing to control heating, ventilation, and air conditioning (HVAC) equipment. They replace traditional pneumatic systems, offering precise control and the ability to integrate with building automation systems. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), DDCs can lead to energy savings of up to 30% in commercial buildings by facilitating advanced scheduling and real-time monitoring of HVAC operations.

The functionality of DDCs is grounded in their ability to analyze data from various sensors throughout a building. They adjust HVAC operations based on real-time environmental conditions, such as temperature, humidity, and occupancy levels. According to the U.S. Department of Energy, implementing advanced control systems, including DDCs, could save buildings 10-25% on energy expenditures. This capability not only helps to maintain the desired indoor climate but also contributes to longer equipment lifespan by preventing unnecessary wear and enhancing reliability. The integration of DDCs with Internet of Things (IoT) technologies further enables remote management and troubleshooting, allowing for prompt adjustments that cater to evolving building needs.

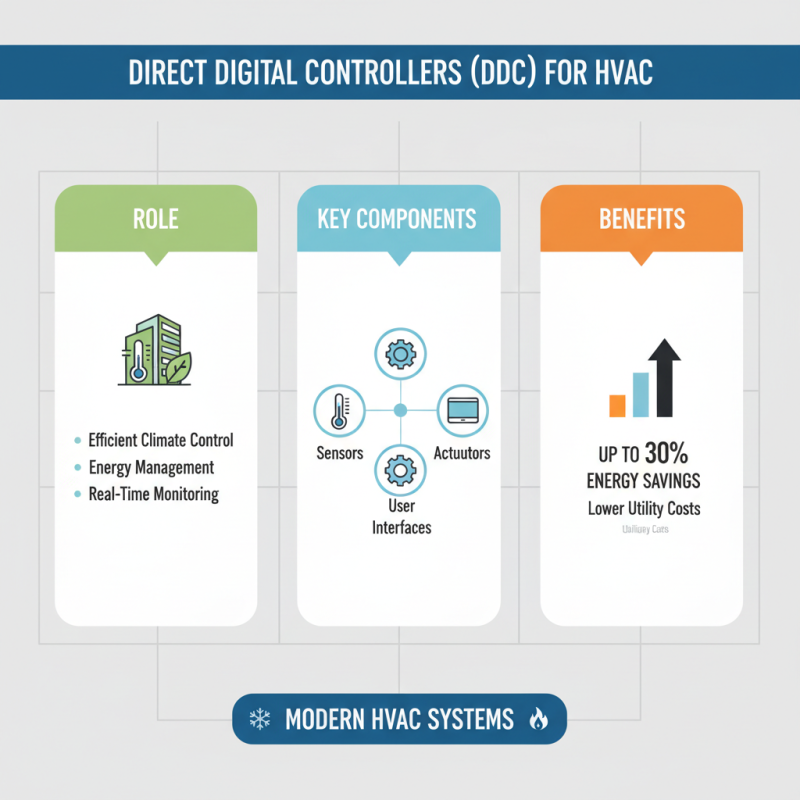

Direct Digital Controllers (DDCs) play a pivotal role in the operation of modern HVAC systems, utilizing advanced digital technology to ensure efficient climate control and energy management. Key components of DDCs include sensors, actuators, and user interfaces, which work together to monitor and adjust heating, ventilation, and air conditioning processes in real time. According to industry reports, the integration of DDC technology can lead to operational energy savings of up to 30%, significantly lowering utility costs for commercial buildings.

Sensors are the backbone of DDC systems, continuously gathering data on environmental conditions such as temperature and humidity. This information is relayed to the controller, which processes it to determine the required adjustments. Actuators then execute these adjustments by regulating airflow, temperature settings, and the operation of various system components. Additionally, user interfaces, often featuring graphical displays, allow facility managers to easily monitor system performance and make manual adjustments when necessary.

Tips: Regularly calibrate sensors to ensure accurate readings, as even minor discrepancies can lead to significant inefficiencies. Additionally, utilizing the data collected by DDCs to perform trend analysis can help identify opportunities for further energy savings and system optimization. Invest in training for personnel to ensure they are well-versed in DDC operation and maintenance, enhancing system reliability and performance.

Direct Digital Controllers (DDCs) have become integral to modern HVAC systems, significantly enhancing energy efficiency and performance. These advanced control systems leverage real-time data to optimize heating, ventilation, and air conditioning processes. According to the U.S. Department of Energy, implementing DDCs can lead to energy savings of 10-30%, as they facilitate precise control over environmental conditions while adjusting to occupancy levels and activity patterns throughout the day.

The energy efficiency gained from DDCs stems from their ability to monitor and adjust energy consumption dynamically. For instance, a report from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) highlights that DDCs streamline system operations by ensuring that equipment runs only when necessary, preventing energy waste. By employing sophisticated algorithms and sensors, DDCs can modulate system output in response to real-time changes, leading to optimally maintained indoor climates without excessive energy use.

Moreover, the integration of DDCs fosters enhanced performance metrics across HVAC systems. Studies indicate that buildings equipped with DDCs can experience improved occupant comfort and indoor air quality, which are pivotal for productivity in commercial environments. The intuitive management capabilities of DDCs not only reduce operational costs but also extend the lifespan of HVAC components by preventing the wear and tear commonly associated with inefficient control practices.

In modern HVAC systems, the implementation of Direct Digital Controllers (DDCs) hinges significantly on the integration of sensors and actuators. Sensors play a crucial role in data acquisition, providing real-time information on various parameters such as temperature, humidity, and pressure. According to a market analysis report by Research and Markets, the global HVAC sensors market is projected to grow at a compound annual growth rate (CAGR) of over 10% from 2021 to 2026, highlighting the increasing reliance on sophisticated sensing technologies in climate control. These sensors enable DDCs to gather precise data, facilitating efficient adjustments to the system’s operations.

Actuators complement sensors by executing the control commands generated by the DDC. They convert the digital signals from the controller into physical action, such as adjusting dampers, valves, or fans to regulate airflow and temperature effectively. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that energy efficiency in HVAC systems can improve by as much as 30% when optimal control strategies are employed through reliable sensors and actuators. This synergy between sensors and actuators ensures that HVAC systems operate in a balanced manner, responding dynamically to changes in environmental conditions, thereby enhancing overall system performance and energy savings.

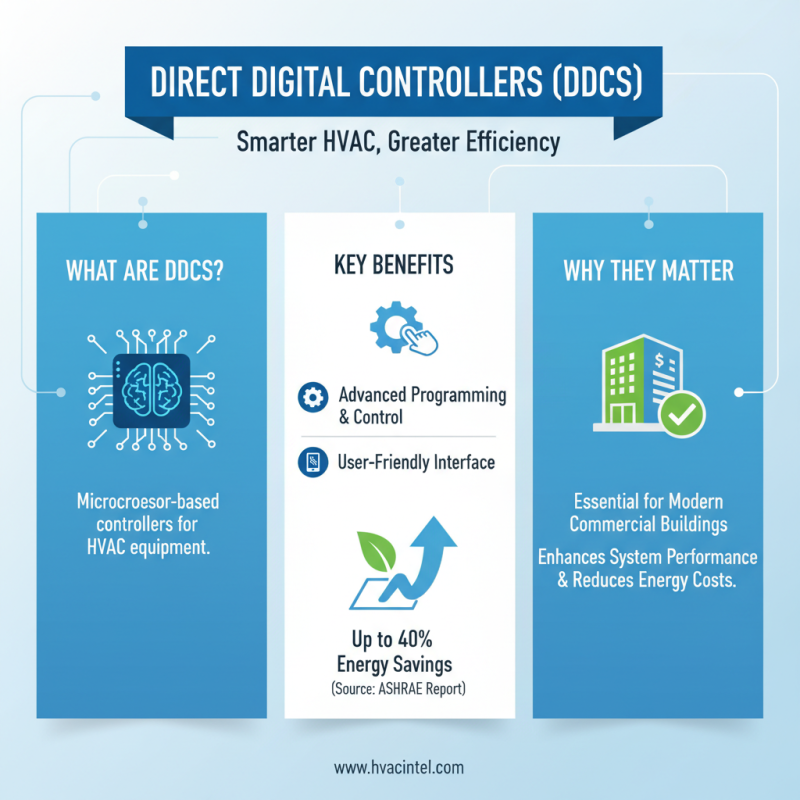

Direct Digital Controllers (DDC) are essential components in modern HVAC systems, providing advanced programming and user-friendly interfaces that significantly enhance system performance and energy efficiency. DDCs utilize microprocessors to monitor and control HVAC equipment dynamically. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), implementing DDCs can lead to energy savings of up to 40% when integrated with effective controls and sensors. This capability makes them increasingly valuable in commercial buildings where energy costs are a significant concern.

The programming aspect of DDCs is particularly noteworthy, as it allows for customization to meet specific building needs. Users can create complex algorithms that automate system responses to varying conditions, such as temperature fluctuations or occupancy changes. The user interface of DDCs is designed to be intuitive and accessible, often featuring touchscreen displays that provide real-time data and visualization of system performance. In fact, a survey by the Building Owners and Managers Association (BOMA) indicated that over 70% of building managers prefer systems with easy-to-navigate interfaces, which significantly reduces training time and improves operational efficiency. This growing trend emphasizes the importance of user-centric design in the development of DDC technologies in HVAC systems.