A DDC controller for HVAC plays a crucial role in modern building management. These systems enhance energy efficiency and climate control. According to the U.S. Department of Energy, well-designed HVAC controls can reduce energy consumption by up to 30%. This translates into significant cost savings. The DDC, or Direct Digital Control, manages heating, cooling, and ventilation effectively.

These controllers utilize software algorithms to monitor and adjust system performance. They collect real-time data from various sensors, leading to responsive adjustments. For example, when outdoor temperatures rise, the DDC controller can increase cooling output efficiently. However, the implementation can be tricky. Many facilities struggle with proper calibration. Industry reports suggest that up to 25% of HVAC systems face issues due to improper DDC configuration.

Moreover, not all DDC controllers are created equal. Choosing the wrong system can lead to inefficiencies and increased energy bills. This highlights the need for thorough research when selecting the right DDC controller for HVAC systems. Attention to these details can pave the way for a truly effective and energy-efficient HVAC operation.

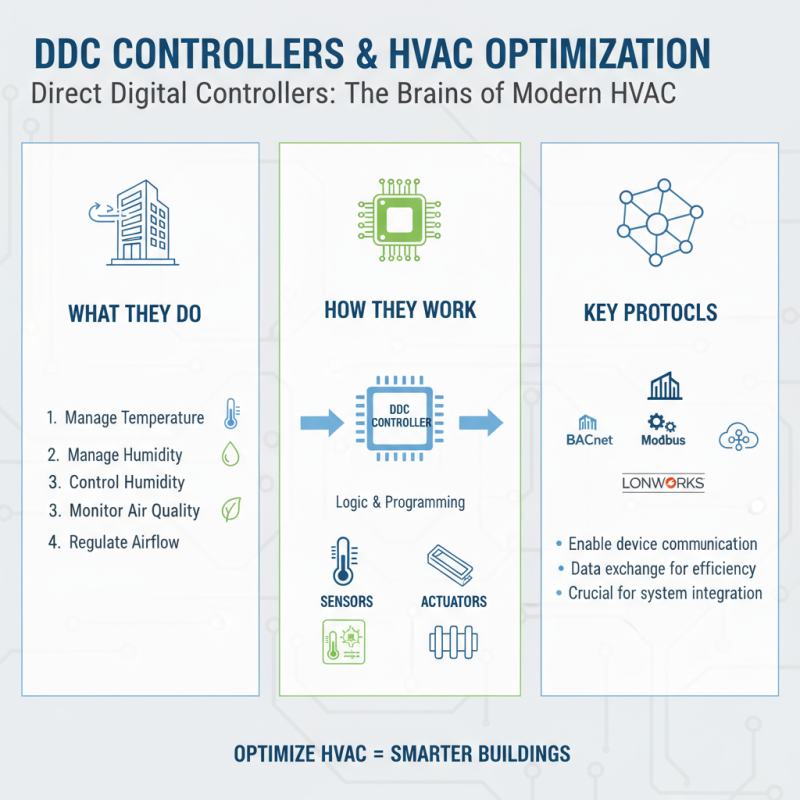

A DDC controller, or Direct Digital Control controller, plays a crucial role in HVAC systems. It manages and monitors the climate control components, ensuring efficient operation. These controllers optimize energy use and improve overall comfort by regulating temperature, humidity, and airflow.

The HVAC market has seen significant growth. According to a recent report, DDC controllers can improve energy efficiency by up to 30%. This reduction not only lowers operational costs but also contributes to a greener environment. Importantly, these controllers enhance system reliability and accuracy, allowing for precise adjustments based on real-time data.

Tips: Regular maintenance is vital for DDC controllers. Check for software updates periodically. Additionally, user training can maximize the controller's capabilities. Remember that even a small programming error can lead to inefficiencies. Keeping an eye on system performance is essential. Make use of analytics to spot anomalies early.

DDC controllers, or Direct Digital Control controllers, are vital components in modern HVAC systems. Their primary function is to monitor and manage heating, ventilation, and air conditioning operations. They do this efficiently, helping to maintain indoor comfort and energy efficiency. These devices utilize sensors and actuators to regulate system performance, adjusting temperatures and airflow in real-time.

One key feature of DDC controllers is their ability to provide precise control. They can be programmed to follow specific schedules or respond to environmental changes. This flexibility allows for tailored heating and cooling strategies. However, with complex programming options, users sometimes face a learning curve. Poorly configured systems can lead to issues, such as inconsistent temperatures or increased energy costs.

Another noteworthy aspect is network capability. DDC controllers can communicate with other building systems. This integration can enhance overall building performance. Yet, not all systems are equally compatible. It requires ongoing assessment and adjustments. Balancing automation with user input remains a challenge. Users must remain engaged to optimize controls effectively.

DDC controllers play a crucial role in enhancing energy efficiency within HVAC systems. These controllers use digital technology to monitor and manage a building's heating, ventilation, and air conditioning. According to a report by the U.S. Department of Energy, using DDC controllers can improve a building's energy efficiency by up to 30%. This is significant for reducing operational costs and minimizing energy consumption.

A DDC controller adjusts HVAC operations based on real-time data. For instance, it can modulate the speed of fans or pumps to match demand. By optimizing performance, it prevents unnecessary energy use. This means a more consistent indoor climate without overworking the system. However, users need to program these controllers correctly. Misconfiguration can lead to inefficiencies and increased energy bills.

Tips: Regularly update the controller's software. This can ensure peak performance. Monitor the system's data trends. Understanding usage patterns can help adjust settings for greater efficiency. Also, consider scheduling routine maintenance checks. Small issues can escalate, leading to larger inefficiencies.

The above chart illustrates the significant reduction in energy consumption after the implementation of DDC controllers in HVAC systems. Prior to DDC implementation, the energy consumption was measured at 12,000 kWh, which decreased to 8,000 kWh post-implementation, showcasing the effectiveness of DDC in enhancing energy efficiency.

DDC controllers, or Direct Digital Controllers, are crucial for HVAC systems. They manage temperature, humidity, and air quality in buildings. Communication protocols play a significant role in how these controllers operate. Understanding these protocols is key to optimizing HVAC performance.

Communication often involves standard protocols like BACnet and Modbus. BACnet allows different devices to talk to each other seamlessly. It uses a message format that includes device IDs and data points. Modbus, on the other hand, is simpler. It sends commands from a master device to slaves. Each has distinct advantages and challenges. For instance, while BACnet supports more complex systems, its setup is often more demanding.

The choice of protocol can affect system responsiveness. Sometimes, devices may struggle to interpret commands. This can lead to delays. Additionally, the complexity of manuals can be overwhelming for technicians. Proper training is essential for ensuring effective communication between devices. Investing time in understanding these elements can enhance HVAC efficiency.

DDC controllers play a crucial role in modern HVAC systems. They enhance efficiency and improve comfort. These controllers utilize digital signals to manage various HVAC components. By doing so, they provide precise control over heating, cooling, and ventilation.

Common applications of DDC controllers include commercial buildings and industrial facilities. In these settings, they help maintain optimal indoor climates. They can adjust airflow based on real-time data, creating a more comfortable atmosphere. Yet, not all installations succeed. Poorly configured systems can lead to energy waste and discomfort.

The benefits of DDC controllers are significant. They allow for remote monitoring, which saves time and resources. Additionally, they help reduce energy consumption, which can lower operating costs. However, the initial setup can be complex and requires careful planning. This complexity may deter some users. Despite these challenges, the advantages often outweigh the hurdles.

| Dimension | Description |

|---|---|

| Function | Automates control of HVAC systems for improved efficiency. |

| Components | Includes sensors, actuators, and controllers. |

| Common Applications | Commercial buildings, residential systems, and industrial settings. |

| Benefits | Energy savings, improved comfort, real-time monitoring. |

| Control Methods | PID control, on/off control, and adaptive control strategies. |

| Integration | Can be integrated with building management systems (BMS). |

| Data Logging | Records temperature, humidity, and energy usage data. |

| User Interface | Accessible via touchscreen or web applications. |